First article inspection at Aisin China kicks into high gear with Geomagic Control X

Inspecting curved surfaces is no piece of cake. A common example in the automotive industry are sunroofs. Primarily used in mid- to high-end cars, they need to be fabricated very precisely and meet high optical performance requirements.

The intricacies of analyzing curved components is something Aisin China, a subsidiary of the world-renowned automotive manufacturer, knows a lot about. Its product range includes electric sliding door systems, locks, interior and exterior handles, and frames.

Always on the lookout for ways to optimize their processes, Aisin engineers adopted 3D scanning for first article inspection and new product development about ten years ago. To this day they continue to reap the rewards of this decision.

3D scanning for curved surfaces

In the case of sunroofs, the advantage of using a scanner for inspection is immediately clear. Traditional tools, like tape measures and callipers, were designed to measure flat surfaces where the depth and angle are consistent. On a curved surface, the depth and angle vary, making it difficult to accurately capture the necessary data points.

Additionally, on a large curved glass, it’s impossible to accurately determine surface deviation with a few data points. A technician inevitably has to carry out multiple measurements to get a clear picture.

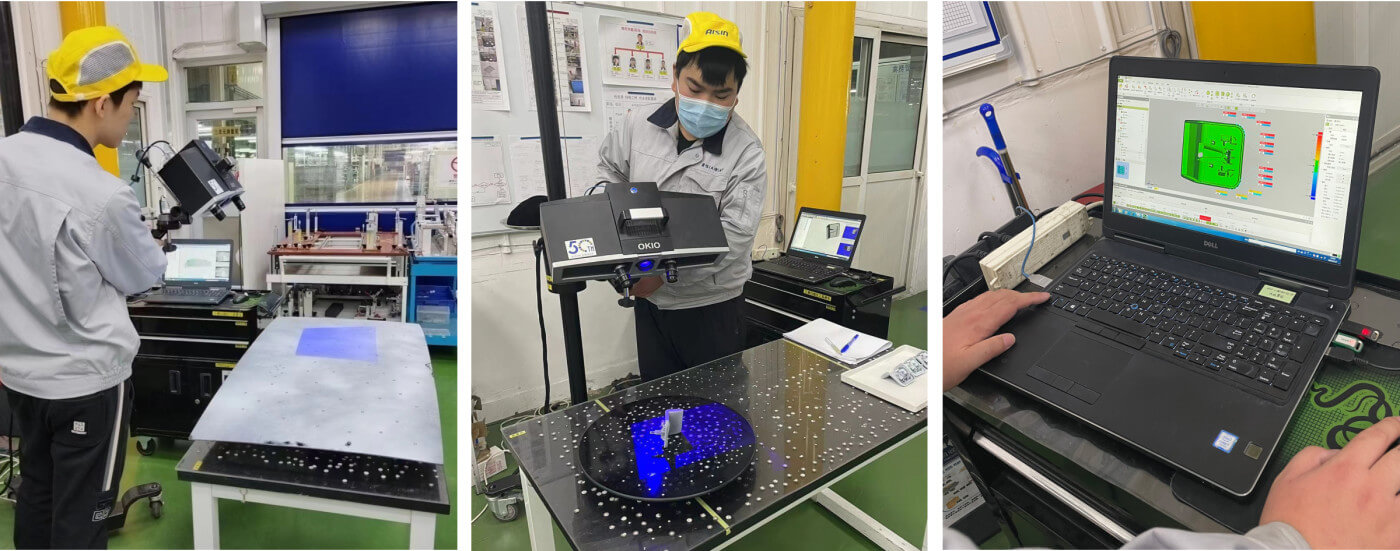

By comparison, 3D scanning yields more detail a lot faster. A scanner captures millions of data points in minutes, resulting in a more accurate picture of the shape. Thus, 3D scanning enhances the inspection team’s efficiency and enables the engineering design team to progress product development more effectively.

And data capture is just the start. Once you get the point cloud, the inspection and design teams begin the analysis. Aisin needed the right 3D scanning software to aid the team with this stage of the inspection process.

They chose Geomagic Control X software because of its ability to identify part deviations and generate analysis reports. By incorporating the software into their process, they digitized their entire workflow and automated inspection.

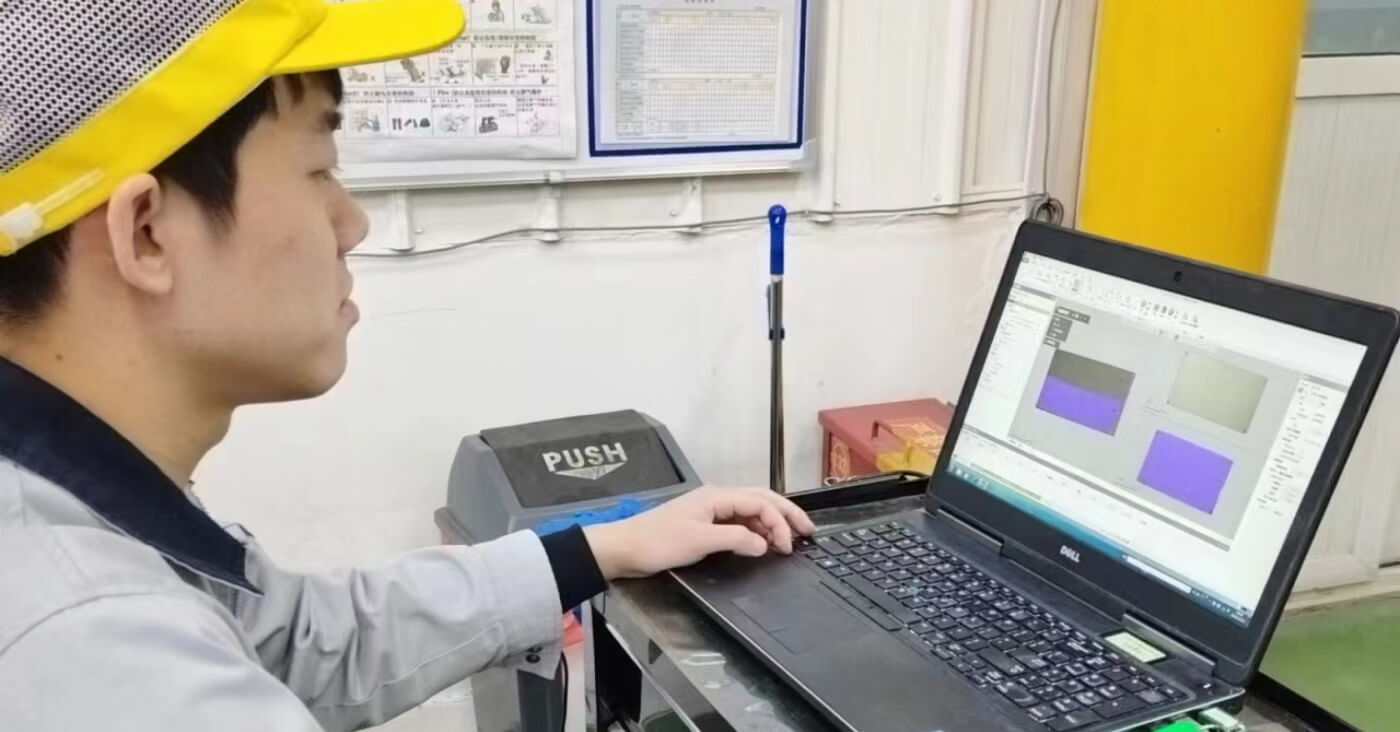

Intuitive deviation colour map for easy inspection

In Aisin workshops, a typical workflow with Geomagic Control X involves processing point cloud data and comparing it with CAD models to calculate deviations and determine if the manufactured parts meet the design requirements.

One tool that has made a world of difference to the quality assurance team is the deviation colour map. It intuitively displays areas of product issues, while the automatically generated inspection reports precisely indicate the problems.

These data-rich visual reports provide valuable feedback. Engineers can quickly pinpoint defects in product design or manufacturing, and use this information to adjust production processes and reduce manufacturing errors, continuously improving the quality of components.

Additionally, Geomagic Control X enabled seamless collaboration between different departments, which led to an increase in the pace of innovation. Engineers, designers, and production experts now have access to the same data, make better decisions and have unified their approach to new product development.

3D scanning brings an enduring advantage

Since the implementation of Geomagic Control X a decade ago, Aisin's quality management system has gone from strength to strength. The 3D metrology software has helped the company increase production efficiency and capacity, while its quality assurance team have the peace of mind that every product delivered to customers meets the highest standards.

The impact of 3D scanning on the automotive sector doesn't stop here. Beyond first article inspection and product development, auto manufacturers are leveraging 3D scanning in countless other ways. You can learn about the applications in the in-depth blog post Everything you need to know about 3D scanning for the automotive industry.

Topics

Subscribe to our newsletter

Get our best content straight in your inbox

Betty Zhuang

Betty Zhuang